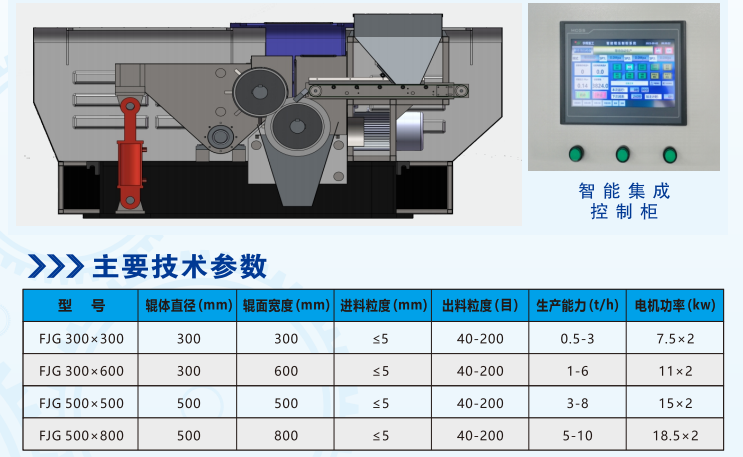

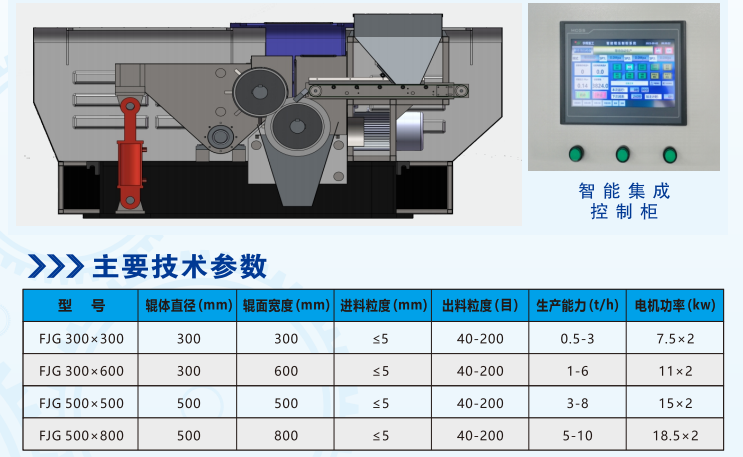

Innovative fully intelligent powder mill

In my country's photovoltaic, electronics, building materials, metallurgy, chemical and other industries, the processing of fine materials such as quartz stone, rocks, ceramic raw materials, chemical raw materials, etc. has always been a thorny problem. In order to solve this problem, the scientific research team of Yuhui Heavy Industry has gone through hard work to develop an innovative fully intelligent powder mill. Its performance characteristics and advantages are eye-catching. It can process various quartz stones, rocks, ceramic raw materials, chemical industry Ultra-fine crushing operations are performed on finely crushed raw materials, such as high-purity quartz sand (photovoltaic glass or glass sand), quartz plates (rock plates), paint additives, activated carbon, graphite, etc. What are the specific advantages?

Performance features and advantages

1. No secondary pollution: The powder-making roller is made of special ceramics, and the parts in contact with the material are made of corrosion-resistant stainless steel or non-metallic materials, so there is no secondary pollution at all. This advantage ensures that the chemical composition and characteristics of the raw materials are maintained and improves the purity of the product.

2. Fully intelligent design: It adopts an intelligent human-machine interface for real-time monitoring and is equipped with a PLC automatic control system, which can adjust the equipment's speed, working pressure and feed volume to achieve intelligent control of the milling effect. This feature meets the different needs of users and improves production efficiency.

3. Adjustable finished product particle size: The product particle size is uniformly distributed, the chemical composition is stable, and the product quality is high. The particle size of the finished product can be adjusted within the range of 0.95mm (20 mesh) - 0.075mm (200 mesh) to meet specific particle size requirements. This advantage helps to increase the added value of products and enhance the core competitiveness of enterprises.

4. High production efficiency: By adjusting the pressure, roller speed and material layer thickness, the one-time forming rate of the material can reach about 40-65%. At the same time, the low-speed operation of the two grinding rollers consumes less power and has the advantages of high efficiency, low noise, and energy saving.

5. Low loss: The grinding roller is made of special ceramics with a Rockwell hardness of above HRC88. Under the same material conditions, its service life is 5-10 times that of other wear-resistant parts.

6. Perfect working performance: Equipped with automatic feeding, automatic uniform feeding, automatic pressure adjustment, and automatic dust collection systems to facilitate operation and improve work efficiency. Environmental protection effect, roller compaction powder, low noise, less dust, good sealing performance of the whole machine, fully in line with national dust emission standards.

The advent of this innovative fully intelligent pulverizer will subvert the traditional pulverizer method and help the high-quality development of my country's photovoltaic, electronics, building materials, metallurgy, chemical and other industries.

选择语言

选择语言

Home

Home Product

Product Telephone

Telephone Message

Message